Five Necessary Techniques for Valve Anticorrosion of Energy-saving Air Compressor

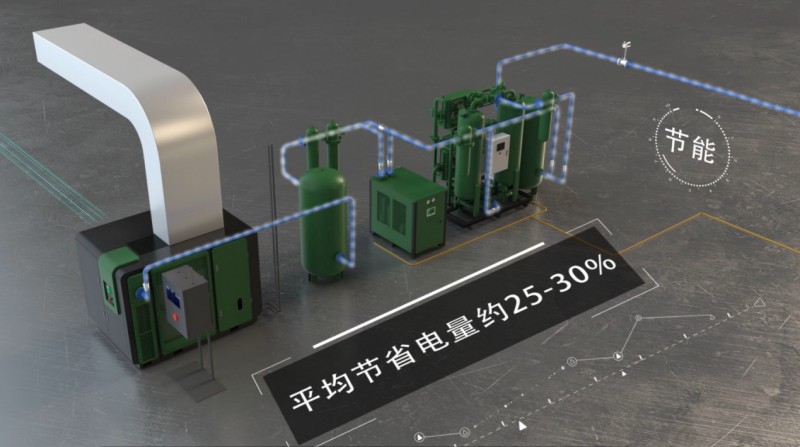

Shanghai Permanent magnet frequency conversionair compressorProcurement optimization sa Zhenenergy conservationair compressor, use for a long time, use more customers.Energy saving air compressor, trustworthy! We constantly pursue quality improvement and energy-saving efficiency progress. The third generation Seize permanent magnet variable frequency two-stage compression screw air compressor saves about 30% electricity on average, and we specialize in "electric tiger". buy Energy saving air compressor Choose Seize, your trusted brand of air compressor!

1.metal surface treatment method

Metal surface treatment processes include sleeping coating, surface infiltration, surface oxidation passivation and so on. Its purpose is to improve the corrosion resistance and mechanical ability of metals.

2. Non-metallic material method is adopted

Non-metallic corrosion resistance is excellent. As long as the service temperature and pressure of the valve meet the requirements of non-metallic materials, it can not only solve the corrosion problem, but also save the common non-metallic materials such as valve body, valve cover, lining and sealing surface of precious metal port valves. As for gaskets and fillers, they are mainly made of non-metallic materials, such as PTFE and chlorinated polyether for oral use, and rubber such as butadiene rubber and Ding Qing rubber for valve lining, while the valve body and valve cover are made of ordinary cast iron and carbon keys, which not only

3.Spray coating method

Coating is the most widely used anti-corrosion means, and it is an indispensable anti-corrosion material and identification mark in air compressor valve products. Coating is also a nonmetallic material, which is usually made of synthetic resin, rubber slurry, vegetable oil, solvent, etc., covering the metal surface, isolating the medium from the atmosphere, and achieving the purpose of anticorrosion.

4.Add corrosion inhibitor

Adding a small amount of other special substances into corrosive media and corrosive substances can greatly slow down the corrosion rate of metals. This special substance is called corrosion inhibitor. The corrosion inhibitor consists of sodium nitrite and sodium chromate, which can make a passivation film on the surface of the valve stem and improve the corrosion resistance of the valve stem. Solvent can make the corrosion inhibitor dissolve slowly and play a lubricating role; Adding zinc powder to asbestos as sacrificial metal, in fact, zinc is also a corrosion inhibitor, which can first combine with chloride in asbestos, so that the contact opportunity between chloride and valve stem metal is greatly reduced, thus achieving the purpose of anticorrosion. If corrosion inhibitors such as red lead and calcium lead acid are added to the coating, the surface of the valve can be sprayed to prevent atmospheric corrosion.

5.Control the corrosive environment

The so-called environment, there are two kinds of broad sense and narrow sense, the broad sense refers to the environment around the valve installation and its internal circulation medium; In a narrow sense, the environment refers to the conditions around the valve installation. Most environments can't be controlled, and the production process can't be changed arbitrarily. Only under the condition that it will not cause damage to products and processes, environmental control methods can be adopted, such as deoxidation of boiler water, adjustment of PH value by caustic soda in oil refining process, etc. Therefore, adding corrosion inhibitor and electrochemical protection also belong to controlling corrosion environment.

Seize specializes in the research, development, production and sales of energy-saving air compressors. The core products are permanent magnet variable frequency two-stage compression screw air compressors.Permanent magnet variable frequency air compressor, two-stage screw air compressor, low-pressure customized energy-saving air compressor, oil-free air compressor, etc., saving 25-30% electricity on average compared with general air compressors.

Seize high-end energy-saving air compressor is widely used in textile, chemical fiber, glass, ceramics, cement, chemical industry and other industries. Its sales volume is nationwide, and its products are exported to Southeast Asia, South Asia and Africa, and are well received by customers.

Seize Air Compressor official website Address: www.seizeair.com.cn;

24-hour hotline: 400-688-1455.

EN

EN  AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS SW

SW GA

GA CY

CY BE

BE IS

IS MK

MK YI

YI HY

HY AZ

AZ EU

EU KA

KA HT

HT UR

UR BN

BN BS

BS CEB

CEB EO

EO GU

GU HA

HA HMN

HMN IG

IG KN

KN KM

KM LO

LO LA

LA MI

MI MR

MR MN

MN NE

NE PA

PA SO

SO TA

TA YO

YO ZU

ZU MY

MY NY

NY KK

KK MG

MG ML

ML SI

SI ST

ST SU

SU TG

TG UZ

UZ AM

AM CO

CO HAW

HAW KU

KU KY

KY LB

LB PS

PS SM

SM GD

GD SN

SN FY

FY