Description

Product introduction

Pressure swing adsorption(PSA)nitrogen generator is an automatic equipment that uses carbon molecular sieve as adsorbent, pressure reduction desorption prin- ciple to adsorb oxygen from the air, thereby separating nitrogen.

Technical indicators

Nitrogen production:1~5000Nm³/h(Standard State)

Nitrogen purity:90%~99.9995%(National Standard Non-oxygen Content)

Nitrogen pressure:0.01~0.8Mpa(Table Pressure Stable And Adjustable)

Nitrogen dew point:-40℃~-70℃(Atmospheric Dew Point)

High quality carbon molecular sieve

High density, compact spring loaded, top/bottom balance, protected by a dedicated pressure sensor

Product characteristics

1. Raw material air is taken from nature. Nitrogen can be produced by supplying compressed air and power.

2. Nitrogen purity can be adjusted conveniently and arbitrarily between 90% and 99.999%.

3. The equipment is highly automated, produces gas quickly, and can be unattended. Nitrogen can be produced within 10-15 minutes of startup.

4. The equipment process is simple, occupies a small area, consumes less energy and costs.

5. Molecular sieves are filled by snowstorm method to avoid the pulverization of molecular sieves caused by high-pressure airflow impact and ensure the long-term use of molecular sieves.

6. On-line inspection of imported analyzer with high accuracy and maintenance-free.

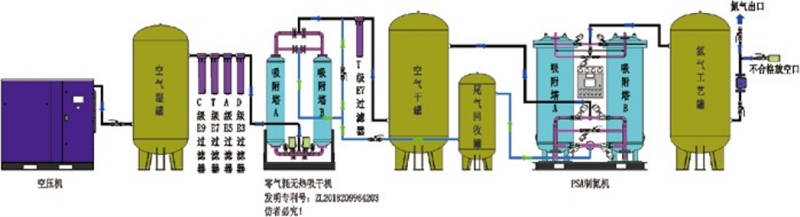

Flow Chart Of Nitrogen Machine

Technical Parameters

Note:The data in this table are based on 0.8 Mpa feed air, 20℃ ambient temperature,0 m gauge and 80% relative temperature.

The data provided in this sample is for reference only.

| 97%(Nitrogen Purity) | |||||

| Model | Nitrogen production (Nm³/h) | Effective airconsum ption (Nm³/min) | Inlet pipe size | Outlet pipe diameter | Host L×W×H |

| SZN97- 20 | 20 | 0. 67 | DN15 | DN15 | 1250* 600*1400 |

| SZN97- 30 | 30 | 1. 00 | DN20 | DN15 | 1250* 600*1850 |

| SZN97- 40 | 40 | 1. 33 | DN20 | DN25 | 1450* 700* 1825 |

| SZN97- 50 | 50 | 1. 67 | DN25 | DN25 | 1150*1130*1900 |

| SZN97- 60 | 60 | 2. 00 | DN25 | DN40 | 1150*1130*1900 |

| SZN97- 80 | 80 | 2. 7 | DN32 | DN40 | 1750* 825* 2090 |

| SZN97- 100 | 100 | 3. 3 | DN32 | DN40 | 1800* 850* 2420 |

| SZN97- 120 | 120 | 4. 0 | DN40 | DN40 | 1800* 850* 2090 |

| SZN97- 150 | 150 | 5. 0 | DN40 | DN40 | 1850* 925* 2100 |

| SZN97- 180 | 180 | 6. 0 | DN50 | DN40 | 1850* 925* 2390 |

| SZN97- 200 | 200 | 6. 7 | DN50 | DN40 | 2000* 950* 2350 |

| SZN97- 250 | 250 | 8. 3 | DN50 | DN50 | 2100*1000*2470 |

| SZN97- 300 | 300 | 10. 0 | DN65 | DN50 | 2100*1100*2530 |

| SZN97- 350 | 350 | 11. 7 | DN65 | DN50 | 2100*1100*2800 |

| SZN97- 400 | 400 | 13. 3 | DN65 | DN80 | 2200*1150*2820 |

| SZN97- 500 | 500 | 16. 7 | DN80 | DN80 | 2350*1400*2870 |

| SZN97- 600 | 600 | 20. 0 | DN80 | DN80 | 2350*1450*3060 |

| SZN97- 800 | 800 | 26. 7 | DN100 | DN80 | 2500*1500*3480 |

| SZN97- 1000 | 1000 | 33. 3 | DN100 | DN100 | 2950*1600*3810 |

| SZN97- 1500 | 1500 | 50. 0 | DN125 | DN100 | 2950*1500*4620 |

| SZN97- 1800 | 1800 | 60. 0 | DN125 | DN100 | 2950*1800*4820 |

| SZN97- 2000 | 2000 | 66. 7 | DN125 | DN100 | 2950*1800*5020 |

| SZN97- 2500 | 2500 | 83. 3 | DN200 | DN100 | 5900*1500*4520 |

| SZN97- 3000 | 3000 | 100. 0 | DN250 | DN125 | 5900*1500*4620 |

Working Environment

EN

EN  AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS SW

SW GA

GA CY

CY BE

BE IS

IS MK

MK YI

YI HY

HY AZ

AZ EU

EU KA

KA HT

HT UR

UR BN

BN BS

BS CEB

CEB EO

EO GU

GU HA

HA HMN

HMN IG

IG KN

KN KM

KM LO

LO LA

LA MI

MI MR

MR MN

MN NE

NE PA

PA SO

SO TA

TA YO

YO ZU

ZU MY

MY NY

NY KK

KK MG

MG ML

ML SI

SI ST

ST SU

SU TG

TG UZ

UZ AM

AM CO

CO HAW

HAW KU

KU KY

KY LB

LB PS

PS SM

SM GD

GD SN

SN FY

FY