Description

Air compressor primary station building

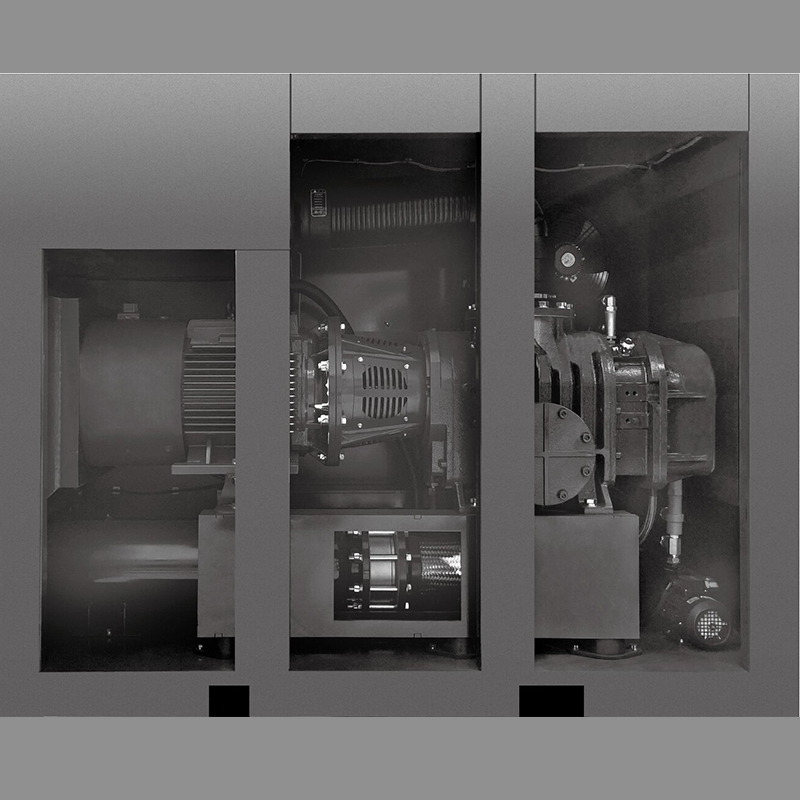

Efficient Host

1. Using high efficiency, large displacement host, cooperate with permanent magnet motor, ensure big displacement while small motor;

2. Large rotor, low speed, high efficiency, low noise, low vibration, low energy consumption;

Independent Oil Pump Forced Lubrication Design

1. Using independently oil pump forced lubrication;

2. Ensure that there is enough fuel injection under extremely low exhaust pressure (2kg) to optimize the oil/gas mixture ratio;

The Customized Enlarged Oil & air Separating System

1. More customized oil separation system to ensure oil and gas separation effect, air oil content less than 2ppm;

2. The internal pressure loss of air compressor is small;

One Textile Company's Case

Originally they used a very famous brand air compressor(Electricity guzzler), 146.6 degrees electricity per hour. Then they changed a domestic brand low pressure, two-stage compression air compressor, 140 degrees per hour, it didnzt reach their expected energy saving performance.

At last they bought our SEIZE PMM and two-stage compression air compressor, 1023 degrees per hour, it can save 40 degrees more than the previous one. Each year they can save: 40x24x30x12=345,600 degrees power, greatly reduced the production cost.

Some Customers'on-site Cases

Production strength

The workshop staff have been engaged in the production of air compressors for a long time, and have accumulated a lot of on-site technical and management experience. The sales elite with 16 years of air compressor sales experience and a team of after-sales engineers with strong air compressor maintenance expertise

Company Qualification

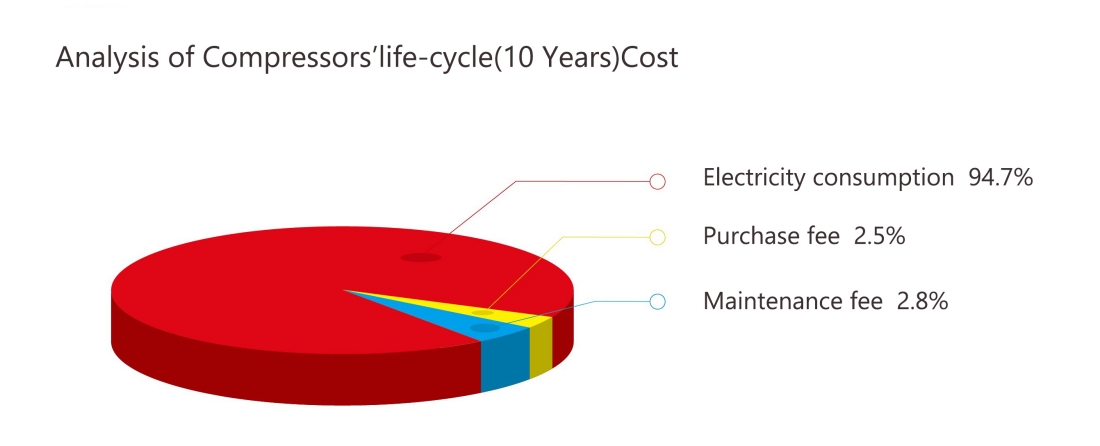

Ten-year operating cost analysis of air compressors

For example: Cost analysis of a 132KW air compressor in 10 years life-cycle

・ Purchase cost is about RMB 300,000 yuan

・ Maintenance cost is on average of ¥35,000 each year, 10 years in total is around ¥350,000

・ Using 24 hours a day, 320 days a year. Loading rate is 100%, electricity price is ¥1/degree

・ 10 years' power cost=132x1.15x24x320x1x10= RMB 11.66 million

・ Total cost of this air compressor in 10 years= 11.66+0.3+0.35= 12.31 million

・ The electricity cost ratio =11.66/12.31=94.7%

・ The maintenance cost ratio = 0.35/1231=2.8%

・ The purchase cost ratio =03/12.31=2.5%

More than 94% of an air compressor using cost comes from energy consumption!!!

You can save more than 25% if use the same power SEIZE customized air compressor for textile industry, which means you can save RMB 3 millions.

Characteristics of air compressors used in the textile industry

1. Normally 24 hours running, environment is tough, dusty, high requirement of quality;

2. High air consumption;

3. Low air pressure;

4. Most of air compressor station are irregular, complex pipeline, big pressure loss;

5. A half manufacture cost comes from air compressor's power consumption.

| Midd | SVC -110A/W II | SVC -120A/W II | SVC -132A/W II | SVC -150A/W II | |

| 4.5kgf/cm2 | 7.7-30.0 | 8.8-35.0 | 9.6-38.3 | 10.5-42.0 | |

| 5.5kgf/cm2 | 7.2-28.2 | 7.9-30.0 | 8.8-35.0 | 9.6-38.3 | |

| 6.5kgf/cm2 | 6.7-26.6 | 7.2-28.2 | 7.8-33.0 | 8.8-35.0 | |

| AIR Delivery 7.5kgf/cm2 | 6.1-24.5 | 6.5-26.0 | 7.2-30.0 | 8.1-33.0 | |

| 10.5kgf/cm2 | 5.1-20.1 | 5.6-22.9 | 6.1-24.1 | 6.5-28.0 | |

| 12.5kgf/cm2 | 4.4-17.3 | 4.7-19.2 | 5.4-21.3 | 6.1-24.3 | |

| Outlet Temperature (°C) | |||||

| Compressor | Outlet Pipe Diameter (inch) | DN100 | DN125 | DN125 | DN125 |

| Transmission method | |||||

| Lubricant Requirement (L) | 120 | 150 | 150 | 150 | |

| Oil content (ppm) | |||||

| Concuss (mm/s) | |||||

| Max Working Ambient | |||||

| Temperature (°C) | |||||

| Power (kW) | 110 | 120 | 132 | 150 | |

| Starting method | |||||

| Electric Motor | Voltage | 380V/440V/660V | |||

| Protection Level | |||||

| Cooler | Control method | ||||

| Fan Power (KW) | 44655 | 4/5.5/4 | 4/5.5 | 5.5/5.5 | |

| Cooling Air Volume | 380/18.8 | 390/20.6 | 410/22.8 | 500/25.8 | |

| Weight (kg) | 4300 | 5000 | 5100 | 5800 | |

| Air-Cooling | External | 1850 | 1920 | 1920 | 1950 |

| Dimension | 1950 | 2060 | 2060 | 2150 | |

| Weight (kg) | 3600 | 5000 | 5100 | 5300 | |

| Water-Cooling | Dimension | 1860 | 2130 | 2130 | 2130 |

Working Environment

EN

EN  AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS SW

SW GA

GA CY

CY BE

BE IS

IS MK

MK YI

YI HY

HY AZ

AZ EU

EU KA

KA HT

HT UR

UR BN

BN BS

BS CEB

CEB EO

EO GU

GU HA

HA HMN

HMN IG

IG KN

KN KM

KM LO

LO LA

LA MI

MI MR

MR MN

MN NE

NE PA

PA SO

SO TA

TA YO

YO ZU

ZU MY

MY NY

NY KK

KK MG

MG ML

ML SI

SI ST

ST SU

SU TG

TG UZ

UZ AM

AM CO

CO HAW

HAW KU

KU KY

KY LB

LB PS

PS SM

SM GD

GD SN

SN FY

FY