Description

Permanent magnet variable frequency twin-screw air compressor

Industry CustomizBil Energy-saving nir Cornpressor Features

■ Using big rotor, low rotary speed, to ensure the high performance of the machine;

■ Enlarging the oil&air separator system, to ensure the oil content of air export <2ppm;

■ The air from low pressure screw machine is clean, reducing the times to clean the nozzle of texturing machine, improving the quality of finished products;

■ Enlarging cooler's cooling area more than 30%, which ensures the normal operation in high temperature in summer;

■ Separately design the compression ration of the host, optimize input specific power;

■ Intelligent control system, adjust the air delivery automatically based on customers' using(variable frequency models);

■ Networking module is optional, you can know the operation of machine through the mobile at anytime anywhere;

Efficient Host

1. Using high efficiency, large displacement host, cooperate with permanent magnet motor, ensure big displacement while small motor;

2. Large rotor, low speed, high efficiency, low noise, low vibration, low energy consumption;

Independent Oil Pump Forced Lubrication Desig

1. Using independently oil pump forced lubrication;

2. Ensure that there is enough fuel injection under extremely low exhaust pressure (2kg) to optimize the oil/gas mixture ratio;

The Customized Enlarged Oil & air Separating System

1. More customized oil separation system to ensure oil and gas separation effect, air oil content less than 2ppm;

2. The internal pressure loss of air compressor is sma

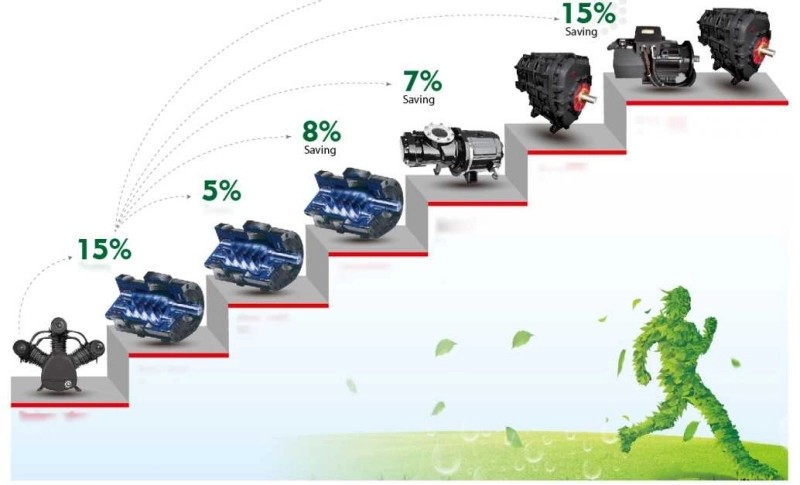

Energy-saving Air Compressor Equipment Flow Chart

1, Two-stage pressure customized host, the average efficiency is increased by 20%

2,Permanent magnet/high-efficiency variable frequency motor: the average efficiency is increased by 5%

3,Double frequency conversion system: constant temperature, constant voltage

4,BW customized large cooling system

5,Customized and enlarged oil circuit and gas circuit system

6,Customized double air intake filter to ensure external air intake

7,Intelligent control system + remote IoT

8.CAmbient temperature design and test standard: 12°C higher than the international standard

9. Overall piping system-stainless steel precision drawn pipe

10. Built-in and reserved heat recovery

Industru CustomizBil Energy-sa wing Hir Compressor rerhnical Parameters

| Model | Max Working pressure (MPa) | Air Deliery (m3/min) | Power (KW) | Transmission Method | L | W | H | Outlet Pipe Diameter | Weight (Kg) |

| SLVC-37A | 3.5-11.5 | 37 | 1800 | 1300 | 1900 | DN80 | 2100 | ||

| SLVC-45A | 3.5-13.8 | 45 | 1800 | 1300 | 1900 | DN80 | 2200 | ||

| SLVC-55A | 4.4-17.6 | 55 | 2290 | 1690 | 1890 | DN100 | 2700 | ||

| SLVC-75A | 5.8-23.1 | 75 | 2420 | 1740 | 2000 | DN125 | 3600 | ||

| SLVC-90A | 7.9-32.0 | 90 | 2900 | 1850 | 1920 | DN125 | 4200 | ||

| SLVC-110A | 9.2-36.8 | 110 | 2900 | 1850 | 1920 | DN125 | 4800 | ||

| SLVC-132A | 11.8-47.2 | 132 | Direct Driven | 3300 | 2050 | 2250 | DN150 | 6000 | |

| SLVC-150A | 0.3 | 12.5-50.0 | 150 | 3300 | 2050 | 2250 | DN150 | 6300 | |

| SLVC-160A | 14.0-56.6 | 160 | 3300 | 2050 | 2250 | DN150 | 6400 | ||

| SLVC-185A | 15.6-62.9 | 185 | 3300 | 2050 | 2250 | DN150 | 6600 | ||

| SLVC-200A | 16.6-67.6 | 200 | 4200 | 2280 | 2400 | DN200 | 8200 | ||

| SLVC-220A | 18.3-73.1 | 220 | 4200 | 2250 | 2400 | DN200 | 8800 | ||

| SLVC-250A | 21.0-83.6 | 250 | 4200 | 2250 | 2400 | DN200 | 9000 | ||

| SLVC-280A | 23.5-93.9 | 280 | 5000 | 2400 | 2600 | DN250 | 9800 | ||

| SLVC-300A | 25.6-102.2 | 300 | 5000 | 2400 | 2600 | DN250 | 10000 | ||

| SLVC-55A | 4.4-17.0 | 55 | 2290 | 1690 | 1890 | DN100 | 2700 | ||

| SLVC-75A | 5.8-22.5 | 75 | 2420 | 1740 | 2000 | DN125 | 3600 | ||

| SLVC-90A | 7.5-29.0 | 90 | 2900 | 1850 | 1920 | DN125 | 4200 | ||

| SLVC-110A | 0.35 | 8.6-34.8 | 110 | Direct Driven | 2900 | 1850 | 1920 | DN125 | 4800 |

| SLVC-132A | 9.8-40.2 | 132 | 2900 | 1850 | 1920 | DN125 | 5000 | ||

| SLVC-150A | 11.8-47.5 | 150 | 3300 | 2050 | 2250 | DN150 | 6300 | ||

| SLVC-160A | 12.5-50.3 | 160 | 3300 | 2050 | 2250 | DN150 | 6400 | ||

| SLVC-185A | 14.0-56.6 | 185 | 3300 | 2050 | 2250 | DN150 | 6600 |

Working Environment

EN

EN  AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ ET

ET GL

GL HU

HU MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS SW

SW GA

GA CY

CY BE

BE IS

IS MK

MK YI

YI HY

HY AZ

AZ EU

EU KA

KA HT

HT UR

UR BN

BN BS

BS CEB

CEB EO

EO GU

GU HA

HA HMN

HMN IG

IG KN

KN KM

KM LO

LO LA

LA MI

MI MR

MR MN

MN NE

NE PA

PA SO

SO TA

TA YO

YO ZU

ZU MY

MY NY

NY KK

KK MG

MG ML

ML SI

SI ST

ST SU

SU TG

TG UZ

UZ AM

AM CO

CO HAW

HAW KU

KU KY

KY LB

LB PS

PS SM

SM GD

GD SN

SN FY

FY